Latest Blogs

DTF Station Prestige R2 vs. Prestige R2 Pro - What Are The Differences and Which One Do You Need?

By Taylor Landesman on Wednesday, April 03, 2024

Navigating the equipment requirements for your screen printing business can be a daunting task, especially when faced with questions like, "Which product will ensure timely order fulfillment?" and "How can I achieve top-notch quality without exceeding my budget?" Fortunately, we're here to provide you with a comprehensive guide on scaling your equipment choices according to your business needs.

DTF Station Prestige R2 vs. Prestige R2 Pro - What Are The Differences and Which One Do You Need?

By Taylor Landesman on Wednesday, March 13, 2024

Navigating the equipment requirements for your screen printing business can be a daunting task, especially when faced with questions like, "Which product will ensure timely order fulfillment?" and "How can I achieve top-notch quality without exceeding my budget?" Fortunately, we're here to provide you with a comprehensive guide on scaling your equipment choices according to your business needs.

Automation for Screen Printing Efficiency: Screen Printing Equipment Options

By Taylor Landesman on Thursday, April 06, 2023

Screen Printing Blogs

Digital Versus Hybrid Printing: What Are They and Who Should Consider It

The screen printing industry is undergoing a printing transition for how t-shirts, hoodies and other garments are decorating. New digital printing technologies are successfully implanting themselves in the decorated garment marketplace as alternatives to traditional screen printing.

The Beginners Guide to Screen Printing T-Shirts

Screen printing stands as a versatile and impactful medium, enabling the creation of custom-designed T-shirts that can exude both personal flair and your band.

Automation for Screen Printing Efficiency: Screen Printing Equipment Options

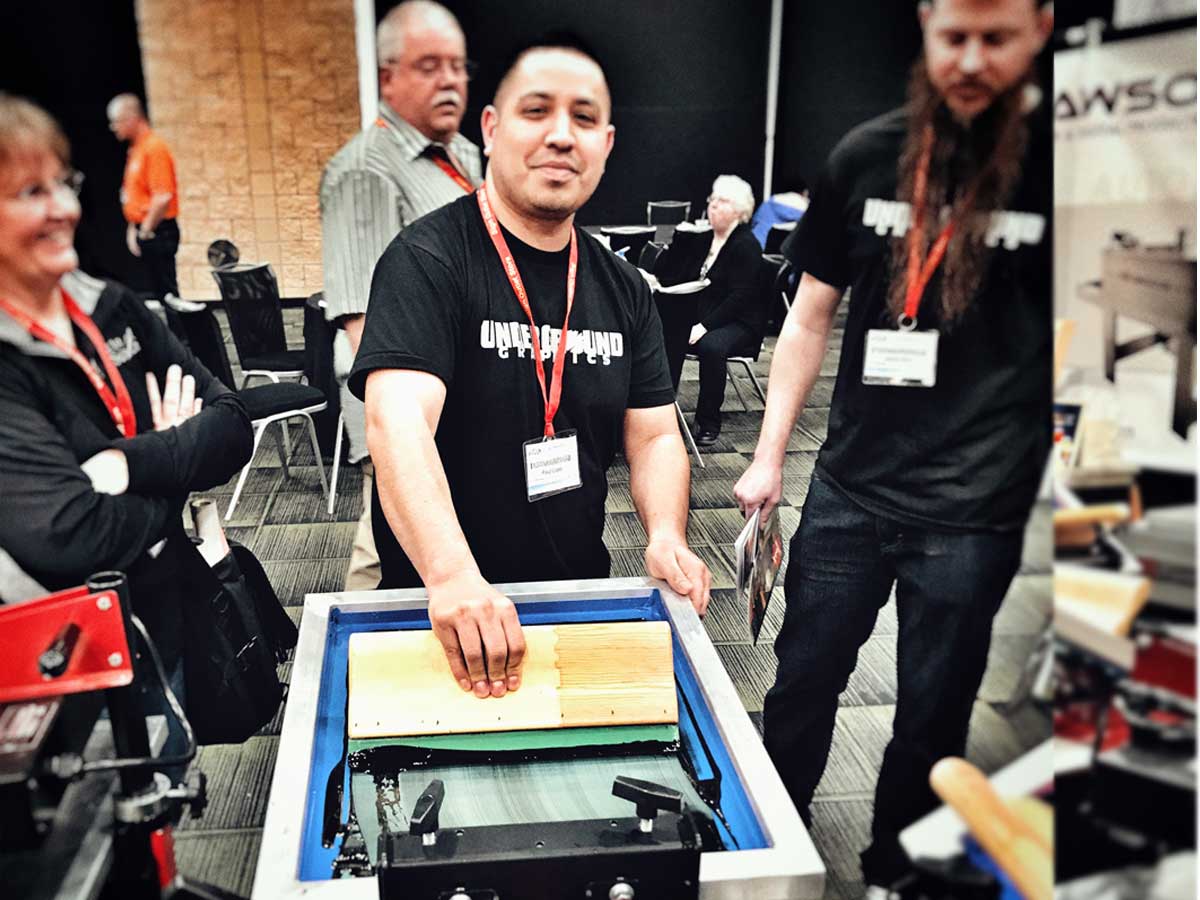

Traditionally a labor-intensive and time-consuming process, screen printing requires experienced and skille...

Twin Express Press/Dryer Combo Machine

The Lawson Twin Express Combo Press/Dryer is a compact 4, or 6 color manual screen printing machine The Eas...

Reasons to Get an Automatic Screen Printing Machine: Going from a Manual to Automatic Press

Most start up screen printers get a manual screen printing press when they first start their business, whil...

Best Practices for Starting Up a Garage or Basement Screen Printing Shop

When starting a screen printing business many people print out of their garage or basement. This is a great...

Digital Printing Blogs

DTF Station Prestige R2 vs. Prestige R2 Pro - What Are The Differences and Which One Do You Need?

Navigating the equipment requirements for your screen printing business can be a daunting task, especially when faced with questions like, "Which product will ensure timely order fulfillment?" and "How can I achieve top-notch quality without exceeding my budget?" Fortunately, we're here to provide you with a comprehensive guide on scaling your equipment choices according to your business needs.

Some Essential Questions to Ask Before Buying a DTF Printer

To ensure that you make a smart investment in a DTF printer, it's important to ask your vendor these pivotal questions.

Exploring DTF Printing: Revolutionizing the World of Apparel Printing

Direct to Film (DTF) printing is a newer, revolutionary technology in apparel printing offering a versatile and ...

Top Blogs

How to Start a Screen Printing Business

Fundamentals about starting up your own screen printing business.

How T-Shirts Are Printed

Read this step by step easy instructions on how to screen print a t-shirt.

When Adding DTG Printing Services Are Good For Business

A guide to help you decide if adding DTG services is a good choice.

How To Increase Revenue Without New Customers

Tips to help you generate more revenue without using paid advertsing.

Education/Training

- Screen Printing How To Tutorial Videos

- Garment Machine Demonstration Videos

- Screen Printing Virtual Solution Center

- In Person Screen Printing Classses

Support Articles

- Plastisol Inks

- Emulsion / Film / Stencils

- Drying & Curing

Quick Links

- View All Screen Printing Blogs

- View All Digital Printing Blogs

- View All Lawson Updates